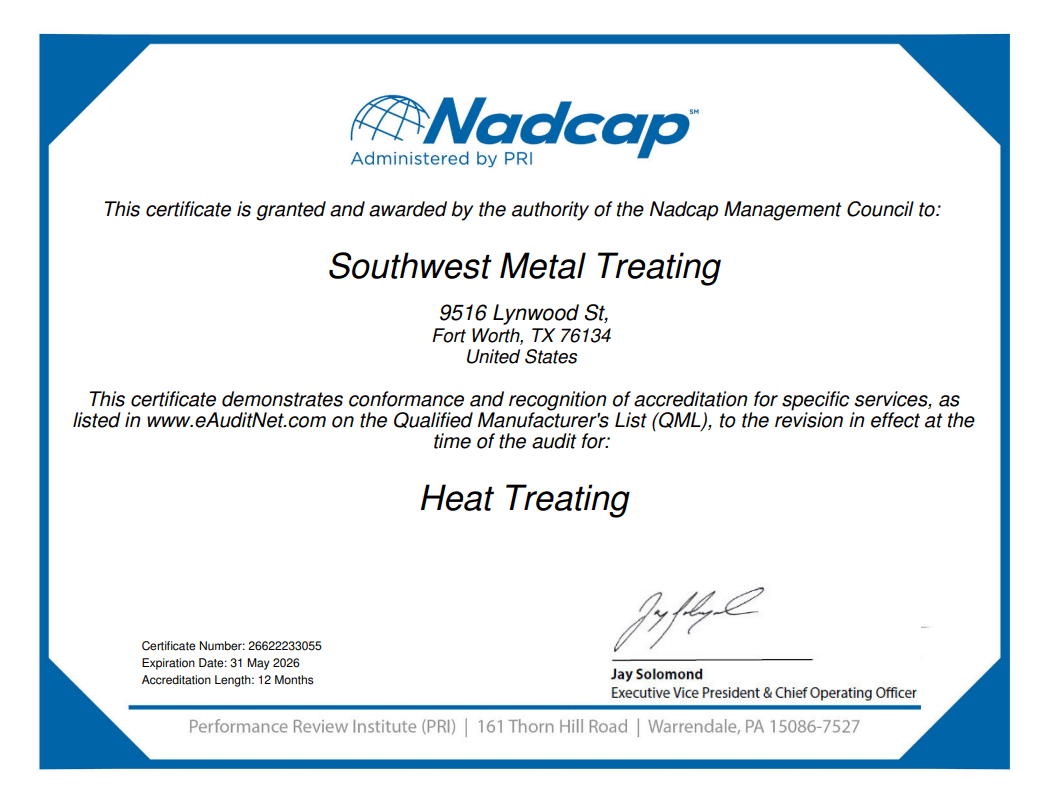

NADCAP Certified Metal Treater

Southwest Metal Treating is NADCAP Certified

Southwest Metal Treating is proud to be a Nadcap certified metal treater, delivering aerospace grade heat treating with verified process controls and consistent, documented results. Backed by more than three decades of experience, we pair precision thermal processing with a quality first mindset to support your most demanding specs, whether you are in the DFW Metroplex or anywhere across the country.

What Does It Mean to Be a NADCAP Certified Heat Treater?

Being a NADCAP certified heat treater means our heat treating processes have been independently audited and verified to meet rigorous industry standards for quality, consistency, and process control. NADCAP certification is widely recognized in aerospace, defense, and other high requirement industries because it is designed to reduce risk in the supply chain. It confirms that a heat treater follows strict procedures, maintains controlled equipment and environments, and produces results that are repeatable from load to load.

For manufacturers, this matters because heat treating directly impacts hardness, strength, fatigue life, and overall part performance. NADCAP certification helps ensure those properties are achieved reliably, not just once, but every time. It also supports tighter traceability and documentation, which is critical when parts must meet customer specifications, material requirements, and regulatory expectations.

What NADCAP Certification Verifies in Heat Treating

A NADCAP audit evaluates how a heat treater manages the details that drive quality and repeatability, including:

- Controlled, documented heat treat procedures

- Qualified equipment and properly maintained furnaces

- Accurate temperature measurement and calibration practices

- Defined quench, atmosphere, and process control requirements when applicable

- Training, qualification, and oversight of personnel

- Inspection, testing, and recordkeeping that support full traceability

- Corrective action systems that prevent repeat issues

Why NADCAP Matters for Your Parts

Choosing a NADCAP certified heat treater helps you protect part integrity and meet demanding requirements with confidence. It can also streamline approvals for aerospace and defense work, reduce the likelihood of rework or nonconformance, and support smoother audits throughout your own quality system. When your components must perform under pressure, certification is one more layer of assurance that the process behind them is controlled, consistent, and proven.

What This Means When You Work With Southwest Metal Treating

For your team, NADCAP certification means you are partnering with a heat treater that prioritizes process discipline and measurable results. You can expect documented controls, reliable repeatability, and the kind of quality mindset required for high performance applications, whether you are producing prototype parts or running long term production.