Stress Relieving

Stress Relieving Services in Dallas-Fort Worth, Texas

Stress relieving is an essential heat treatment process designed to enhance the stability and performance of metal components by reducing internal stresses. Southwest Metal Treating, located in the dynamic Dallas-Fort Worth, TX area, offers specialized stress relieving services backed by over 30 years of industry expertise. Our advanced furnace equipment technology ensures top-quality heat treatment solutions for a wide range of industries, including machine shops, oil & gas operations, aerospace, cutlery & hand tool manufacturing, turbine manufacturing, stamping companies, and forging companies. Our unwavering commitment to precision and meticulous attention to detail ensure that every component meets the highest standards of quality.

Benefits

- Reduced Residual Stresses: Minimizes internal stresses that can lead to distortion or failure, improving component longevity.

- Dimensional Stability: Enhances the dimensional accuracy of components, crucial for precision applications.

- Consistent Performance: Ensures reliable performance and structural integrity under operational stresses.

Process Details

- Thorough Assessment: We begin with an in-depth evaluation of the metal's properties and intended use to determine optimal stress-relieving parameters.

- Controlled Heating: Metals are uniformly heated to a specific temperature to alleviate residual stresses without altering the material's inherent properties.

- Slow Cooling: A carefully controlled cooling process ensures the redistribution of internal stresses, enhancing dimensional stability and performance.

Application and Materials

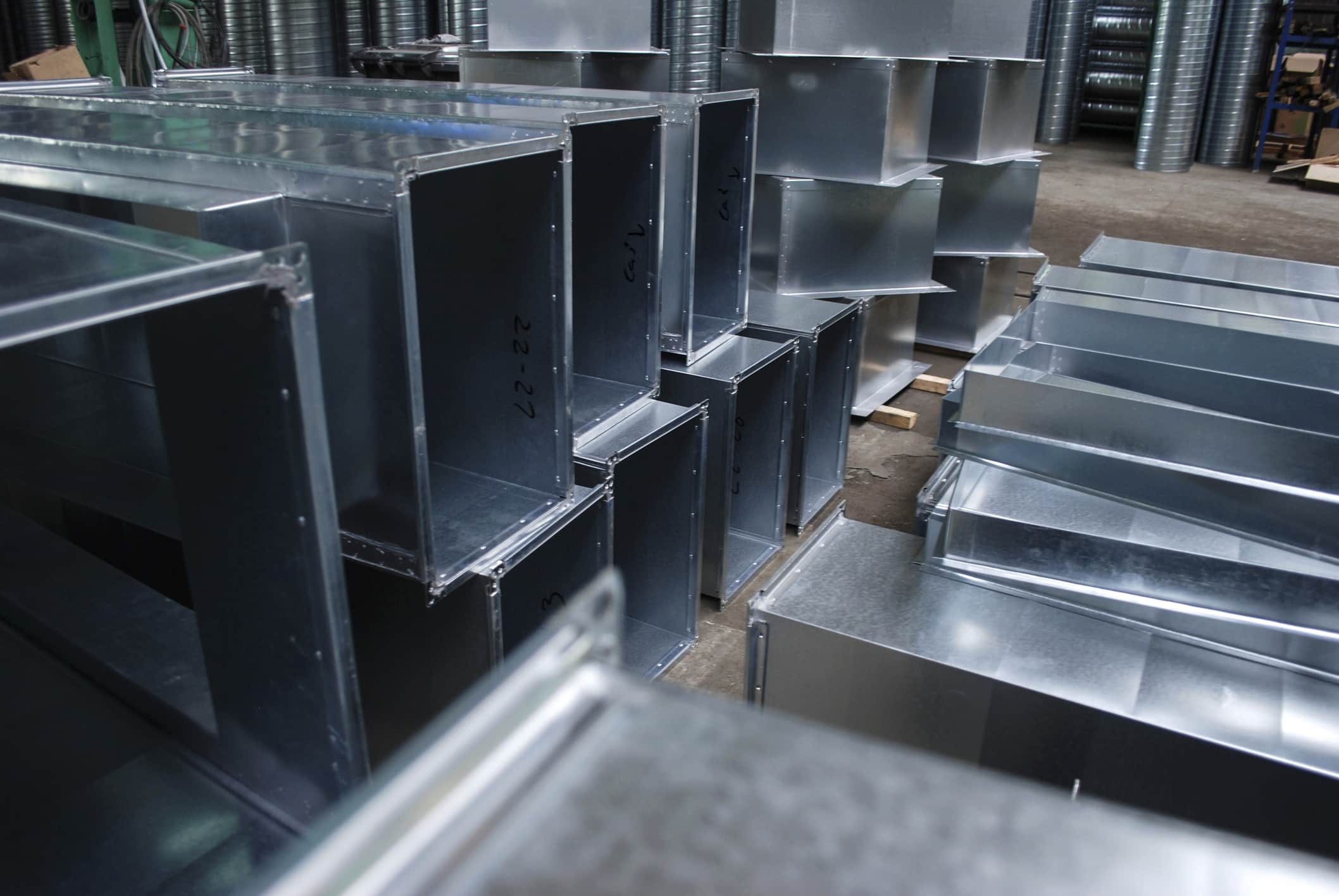

Stress relieving is applied to reduce residual stresses in materials, enhancing their dimensional stability and mechanical properties. Common applications include structural components, such as beams and columns in construction, where stress relief mitigates the risk of distortion and failure. In the manufacturing industry, machined parts, weldments, and pressure vessels benefit from stress relieving to prevent cracks and improve durability. Materials that commonly undergo this process include carbon steels, stainless steels, and certain aluminum alloys, ensuring enhanced performance and longevity. Stress relieving is vital in industries such as aerospace, automotive, and heavy machinery for optimal performance.

Why Work with Southwest Metal Treating

With a combination of cutting-edge technology and extensive experience, Southwest Metal Treating excels in delivering superior stress relieving services. Our expert team is dedicated to providing heat treatment solutions that are precisely tailored to the unique requirements of each industry we serve. We consistently exceed client expectations, ensuring our stress relieving services deliver dependable performance even under the most demanding conditions.

Request a Quote Today

Improve the stability and effectiveness of your metal components with our specialized stress relieving services. Request a quote from Southwest Metal Treating today and discover how our precision-focused approach can enhance your products. Our experienced team is ready to deliver customized solutions that align with your specific industry needs. Reach out now to experience unmatched service and expertise in the field.